PTFE/PPS/PEEK/ACETAL/PA6/UPE/PCTFE

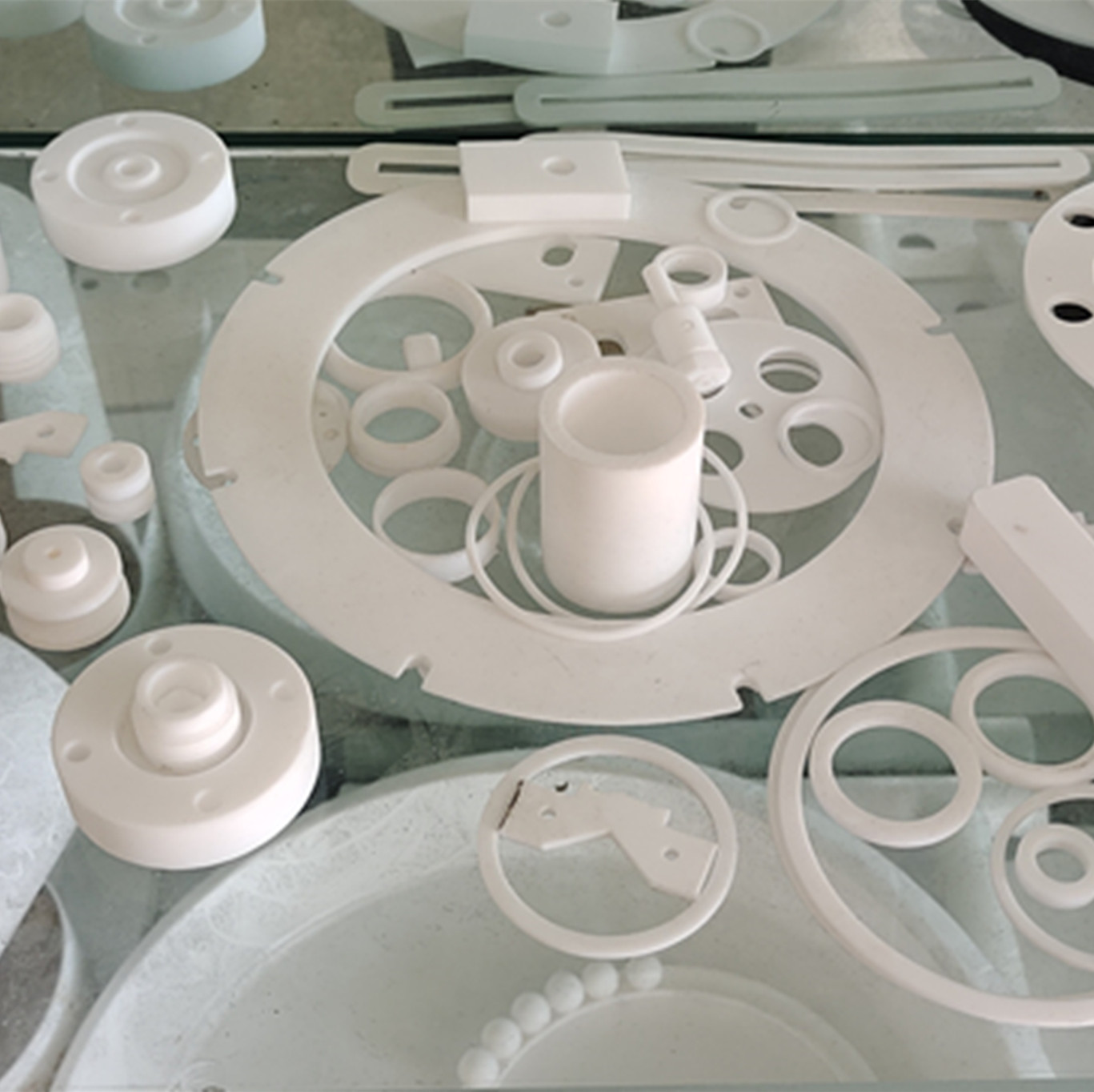

CNC Machined Parts

Washers,Bushing,O-Ring,Valve Seat, Compressor Seals, Spacers,Nuts,Bearing Sleeves

Bearing Sleeve,Screw,Nurts,Bolts,Bushing,Plugs,Fitting

Extrusion PTFE Sheet

Thickness: 10mm to 60mm

Width: 500mm To 1270mm

Length: As your required

150 Tons of PTFE Sheet/Roll Each Month

Thickness: 0.2mm to 10mm

Length: As your required

Modified PTFE Sealing Gaskets, Insulating...

Special Service of Hydrogen Energy

ADVANTAGES

21 Years

Manufacturing & Exporting

99.5%

To be Satisified

25000㎡

Two Factories

60

Exporting to Countries

2500T

Annual Production Capacity

TRADE FAIR

EXHIBITION

About AIDMER

20 YEARS FOCUS

Excellent Quality Comes From Professional Services

20 years of development, the company has formed an industrial sealing material and products with fluorine plastics as the center and polytetrafluoroethylene series and modified PTFE as the leading. Products are widely used in petroleum, petrochemical, electronics, electrical, power cable, power station, refinery, medicine, food processing, chemical industry, papermaking, shipbuilding, machinery accessories and other industries.

Products was export to more than 60 countries and regions, such as Europe, central and South America, Middle East, Africa, South- Asia.

-

Certificate of QUALITY MANAGEMENT SYSTEM

QUALITY MANAGEMENT SYSTEM CERTIFICATE OF CONFORMITY.

GB/T 19001-2016/ISO 9001:2015넶38 2022-07-14 -

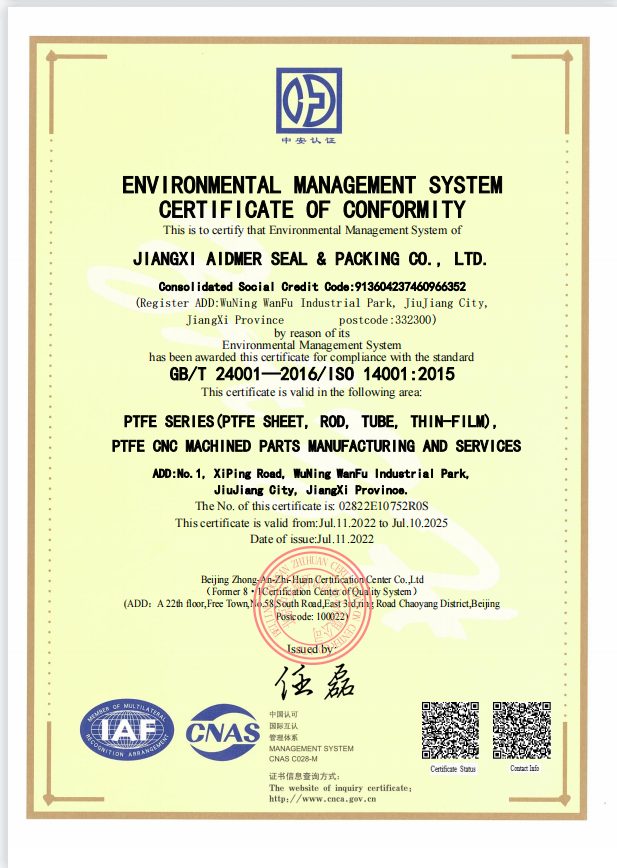

Certificate of ENVIRONMENTAL MANAGEMENT SYSTEM

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE OF CONFORMITY.

GB/T 24001-2016/ISO 14001:2015넶49 2022-07-14 -

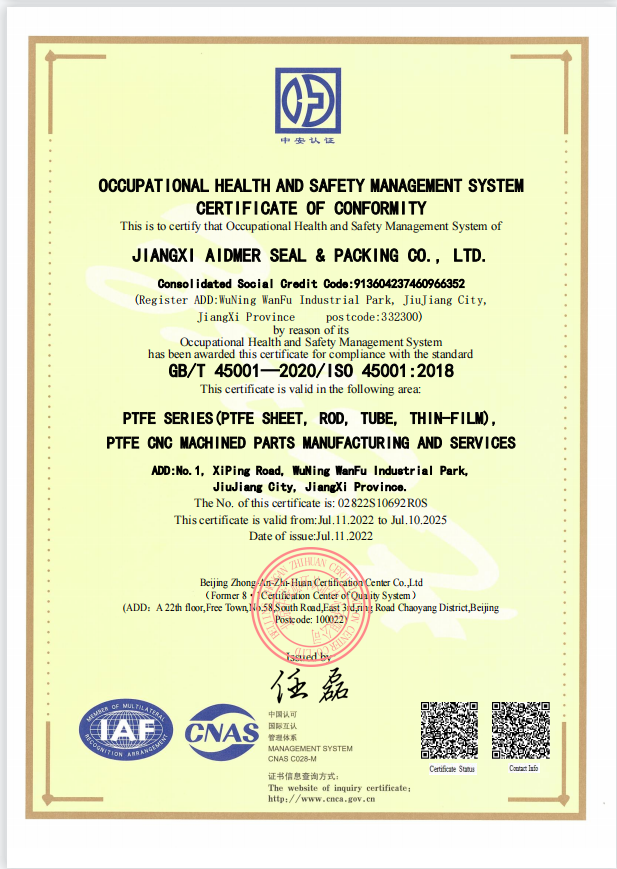

Certificate of OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT SYSTEM

OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT SYSTEM CERTIFICATE OF CONFORMITY.

GB/T 45001-2020/ISO 45001:2018넶33 2022-07-14

SUPPORT

-

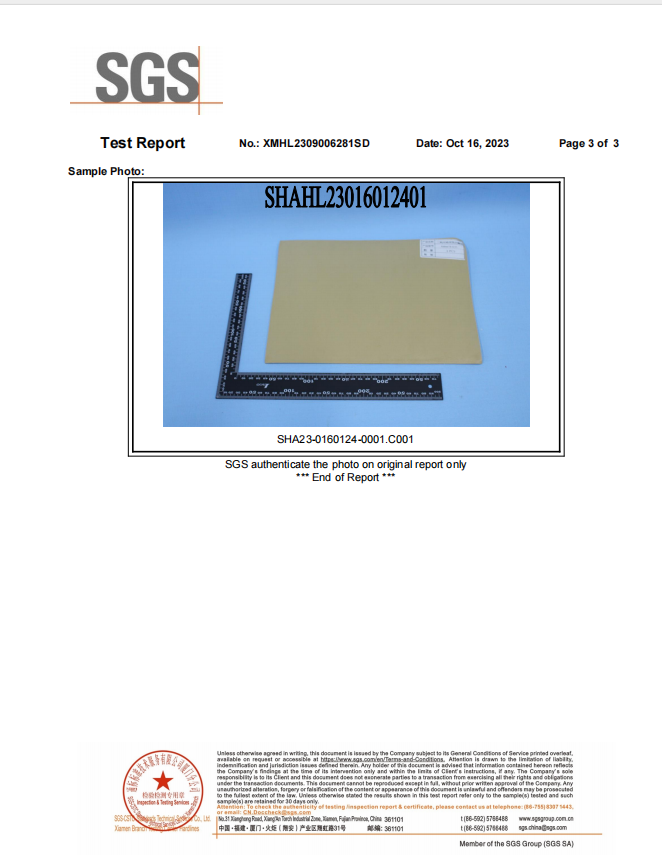

Aidmer78-052BS Barium Sulfate Filled PTFE Sheet was Approval FDA Certificate by SGS

Aidmer78-052BS Barium Sulfate Filled PTFE Sheet was Approval FDA Certificate by SGS

넶4 2023-12-30 -

Aidmer78-052GM Blue glass microspheres Filled PTFE Sheet was approval by FDA Certificate

Aidmer78-052GM Blue glass microspheres Filled PTFE Sheet was approval by FDA Certificate

넶11 2023-12-30 -

Aidmer78-021S Silica Filled PTFE Sheet was approval by FDA Certificate

Aidmer78-021S Silica Filled PTFE Sheet was approval by FDA Certificate

넶4 2023-12-30

PRODUCTS

PTFE Semi-Finished

Sheet/Rod/Tube/Thin-Film

CNC Machined Parts

PTFE, PPS, PEEK, ACETAL, UPE, PA6 etc

Bearing & Sleeve

Plastic Bearing,Flange sleeve

Modified PTFE

Filled:GF,Graphite,Silica, Bronze, Barium Sulfate, Hollow Glass Microspheres

Engineering Plastics

Acetal,PA6,HDPE,UPE,PPS, PEEK

Mr.Alex

Scan to Add WeChat

About Aidmer

News

Products

Industries

Support

Materials

JiangXi Aidmer Seal & Packing Co.,Ltd. TEL:+86-(0)792-2837 628 ; 2838 188 E-Mail: Sales@aidmer.com